Three-dimensional Laser Cutting Technology: Principle, Application, and Future Development Trends

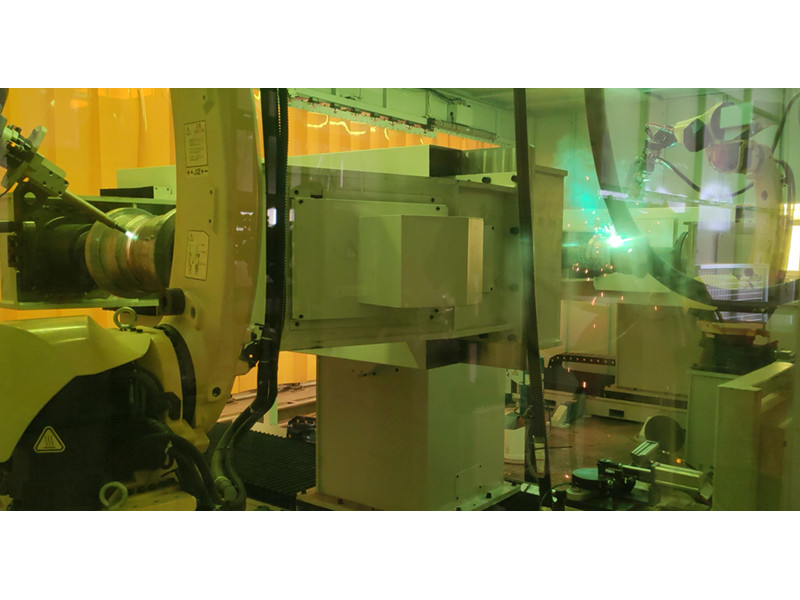

With its high precision and efficiency, three-dimensional laser cutting technology has become one of the core processes in modern manufacturing. It uses a high-energy laser beam to achieve precise processing of complex geometric shapes and is widely applied in high-tech fields such as automotive, aerospace, and medical equipment.

Core Principle

This technology focuses a high-power-density laser beam on the material surface, instantly raising the local temperature to thousands of degrees Celsius, causing the material to quickly melt or vaporize. At the same time, coaxial high-pressure gas (such as oxygen or nitrogen) blows away the molten slag to form a smooth cutting seam. The entire process is precisely controlled by a numerical control system for the cutting path, enabling complex forming of three-dimensional curved surfaces.

Industry Applications

1. Automobile Manufacturing: Used for processing complex parts such as engine hoods and body frames to meet the requirements of lightweight design.

2. Aerospace: Cuts high-temperature-resistant materials such as aluminum alloy and titanium alloy, suitable for aircraft skins and engine components.

3. Medical Devices: Precision cuts micro high-precision parts such as surgical instruments and implants.

4. Consumer Electronics: Processes metal mobile phone casings and electronic component connectors to ensure structural precision.

The materials that can be processed cover metals such as stainless steel, carbon steel, aluminum alloy, copper, and titanium alloy, as well as some non-metallic composite materials, meeting diverse industrial needs.

Technical Advantages

- Ultra-high Precision: The cutting precision can reach ±0.05mm, and the cutting width is only 0.1 - 0.3mm, reducing subsequent processing procedures.

- Efficient Production: The cutting speed can reach several meters per minute, significantly improving production efficiency.

- Non-contact Processing: Avoids mechanical stress deformation of materials and is suitable for fine processing of thin plates and fragile materials.

- Environmental Protection and Energy Saving: There is no tool wear, high material utilization rate, and reduced waste generation.

Key Technological Breakthroughs

1. Intelligent Control: Combines CAD/CAM systems and AI algorithms to achieve automatic path optimization and real-time quality monitoring.

2. Multi-process Integration: Integrates cutting, welding, and heat treatment into the same equipment to form a multi-functional processing center.

3. High-power Lasers: The power of new light sources such as fiber lasers has been increased to the ten-thousand-watt level, greatly improving the cutting speed and thickness capacity.

Future Trends

With the advancement of Industry 4.0, three-dimensional laser cutting technology will develop in the directions of intelligence and specialization:

- Integration into Smart Factories: Realizes equipment networking and remote monitoring through Internet of Things technology to improve the automation level of the entire process.

- Processing of Special Materials: Expands the application scenarios of difficult-to-process materials such as high-temperature alloys and ceramics.

- Green Manufacturing: Optimizes energy utilization rate, reduces carbon emissions, and aligns with sustainable development goals.

Currently, the global manufacturing industry is accelerating the adoption of this technology to replace traditional stamping and milling processes. Its market penetration rate is expected to increase by more than 30% in the next five years. From precision electronic components to large aerospace components, three-dimensional laser cutting technology is constantly breaking through processing limits and providing core support for industrial innovation.