APPLICATION

APPLICATION

ABOUT US

Jiangsu Dade Heavy Industry Co., Ltd. (stock code: 870547) is a high-tech enterprise with independent knowledge industry that integrates research and development, manufacturing, sales and services. The company has a registered capital of 13 million yuan, total assets of approximately 150 million yuan, and nearly 600 employees. It is located in Sunshine Industrial Park, Xishan District, Wuxi City, Jiangsu Province, covering an area of 100000 square meters.

CASE

CERTIFICATE

NEWS

1. Core Working Principle of Friction Welding Friction welding is a solid-state welding process that generates heat through mechanical friction between the surfaces of two workpieces, then applies axial pressure to forge the heated interfaces into a metallurgical bond. Unlike fusion welding methods, friction welding does not melt the base metals completely; instead, it raises the temperature of the faying surfaces to a plasticized state (below the melting point of the base materials). The combined action of frictional heat and axial forging pressure eliminates surface oxides and contaminants, breaks down the surface asperities, and promotes atomic diffusion and recrystallization at the interface, forming a dense, defect-free weld joint. 2. Main Classifications and Technical...

As a core equipment in modern intelligent manufacturing, fiber laser cutting machines have revolutionized the production mode of metal processing with their advantages of high precision, high efficiency, and multi-material adaptability. Driven by technological iterations and the upgrading of downstream industry demands, the global fiber laser cutting equipment market has maintained steady growth. It is expected that the global market size will exceed 28 billion USD by 2032, with a compound annual growth rate (CAGR) of 8.26% . This article systematically analyzes the core application fields, technical advantages, and future development trends of fiber laser cutting machines, providing professional references for industry practitioners and decision-makers. 1. Core Application Fie...

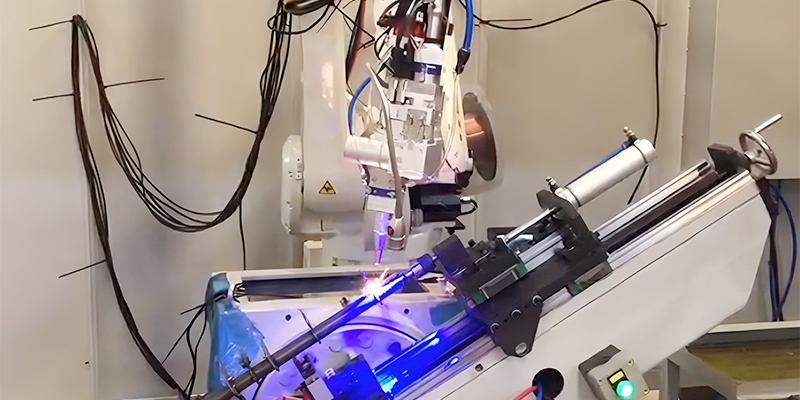

Tube-sheet welding is a critical joining process for manufacturing heat exchangers, boilers, pressure vessels, and chemical reactors—core equipment in petrochemical, nuclear power, and HVAC industries. The quality of tube-sheet weld joints directly determines the pressure-bearing capacity, leak tightness, and service life of these devices. Tube-sheet welding machines are specialized automated systems designed to realize high-precision, high-efficiency welding between tubes (hollow cylindrical components) and tube sheets (thick metal plates with dense hole arrays). This article systematically analyzes the core working principles, technical configurations, key advantages, and application standards of tube-sheet welding machines. 1. Core Working Principles of Tube-Sheet Weld...

2026-02-23

Ship Welding Technology Innovation: Analysis Of High-Efficiency Processes And Intelligent Development Trends2026-02-20

Comprehensive Analysis Of Submerged Arc Welding: Working Principle, Core Advantages And Application Scenarios2026-02-16

High-Efficiency Automated Laser Welding Workstations: An Analysis Of Core Advantages And Future Development Trends2026-02-13

Comprehensive Analysis Of Steel Structure Welding Methods And Core Precautions2026-02-09

MACHINE PURCHASE GUIDE AND SERVICES

Pre-Purchase Analysis

Pre-Purchase Analysis

Before purchasing, please provide the Application drawings or samples you intend to process. Our professional engineering team will conduct a technical analysis and evaluation.

Solution Proposal

Solution Proposal

Based on your Application processing requirements, our engineers will recommend the most suitable equipment and corresponding fixture solutions.

Equipment Purchase

Equipment Purchase

Once satisfied, you may sign a purchase contract and join our esteemed customer network.

Equipment Delivery

Equipment Delivery

Within the agreed delivery period, we will transport the highest-quality Applications to your factory for on-site handover.

Installation Debugging

Installation Debugging

Upon arrival, our professional engineers will install, debug, and provide essential operational guidelines.

Technical Guidance

Technical Guidance

Our engineers will offer technical training to your operators to ensure the processed Applications meet desired specifications.

We provide one-on-one consultative services, offering industry and equipment-related information.

1. Our sales team will thoroughly understand your processing needs and tailor equipment solutions accordingly.

2. We provide industry insights to help you stay informed about market trends.

After signing the contract (or upon purchase intent), we offer comprehensive support.

1. Customized processing solutions and machine selection based on your Application characteristics and Applicationion capacity.

2. Services including cycle time analysis, equipment selection, fixture design, factory layout planning, and free sample processing.

3. Zero-basics technical training. Our engineers will train your operators to meet processing requirements.

Service Commitment: Continuously providing Application consultations, technical guidance, and training is the cornerstone of our development.

MESSAGE