Usage environment

Three-phase AC power supply: 380V (±10%), 50Hz

Single-phase AC power supply: 220V (±10%), 50Hz

Ambient temperature: -20°C to 45°C

Humidity: 50% to 90%

Compressed air: 0.5MPa to 0.7MPa

Welding conditions

Welding method: Rich argon gas-shielded arc welding (80% Ar + 20% CO₂)

Welding position: Flat welding (fillet welding in the horizontal position), horizontal fillet welding

Welding wire: 1.2mm solid wire

Wire extension length: 22mm

Welding oscillation width: 0–30mm

Applicable workpieces

Workpiece name: Vibration exciter

Workpiece specifications: Maximum weight 161kg

Weld seam type: As per the weld requirements indicated in the customer's product drawings

Process flow

Impact-type vibration exciter process flow:

Single-part machining → Complete assembly → Complete welding

Non-impact-type vibration exciter process flow:

Single-part machining → Internal rib plate assembly and welding → Complete assembly → Complete welding

Production Line Requirements:

Use a power-assisted robotic arm to lift single parts (eccentric blocks, central shafts, etc.) onto the assembly fixture. The supplier must design suitable lifting tools to facilitate the handling of components and finished products. The lifted parts must remain level, saving time and effort while ensuring easy assembly.

After manual assembly, tacking, and welding (internal welds) on the fixture, the workpiece is automatically transported to the conveyor line.

The workpiece is then automatically transferred to the welding positioner, which clamps it automatically and rotates to the desired angle (360° adjustable). The welding robot performs automatic welding.

After welding, the positioner moves to the manual grinding area, where workers grind the workpiece while the positioner rotates and tilts for full accessibility.

Once grinding is complete, the positioner moves to the output line, releases the workpiece automatically, and a power-assisted arm lifts it onto the material storage rack.

The production line design must consider the placement of materials at each stage to facilitate easy handling.

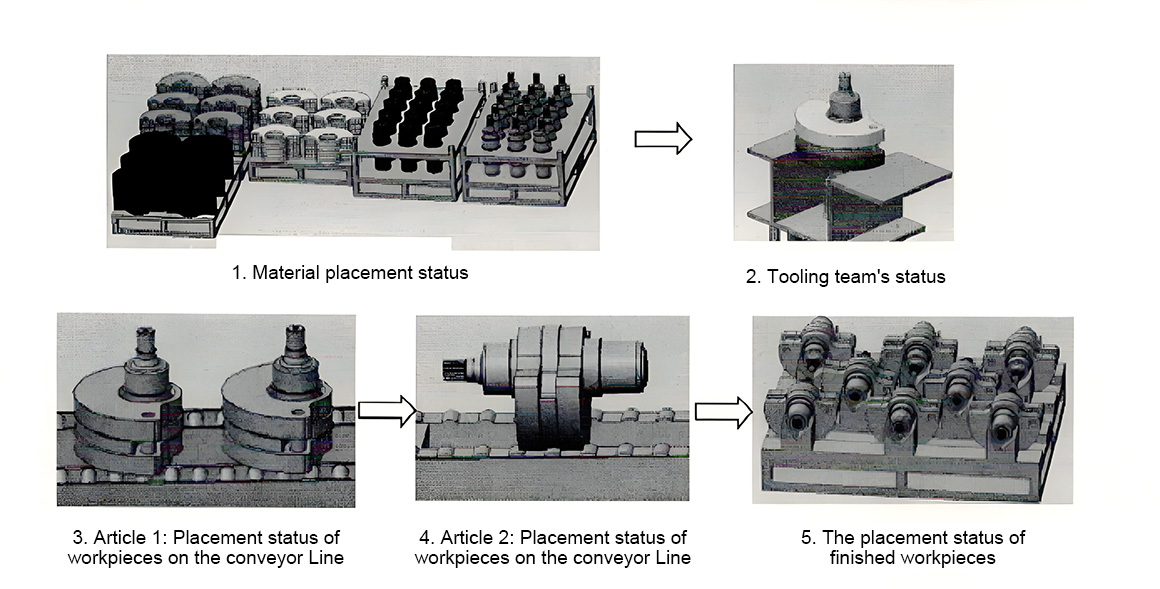

The placement status of materials during each process is as follows: