Robotic welding systems have become synonymous with efficiency, precision, and consistency in modern manufacturing—revolutionizing production lines in automotive, aerospace, and heavy industry. Yet, their adoption is not without tradeoffs. For businesses considering welding automation, understanding the inherent limitations—from financial barriers to technical constraints—is critical to avoiding costly missteps. This analysis breaks down the key disadvantages of robotic welding, helping manufacturers evaluate whether automation aligns with their operational needs, budget, and long-term goals.

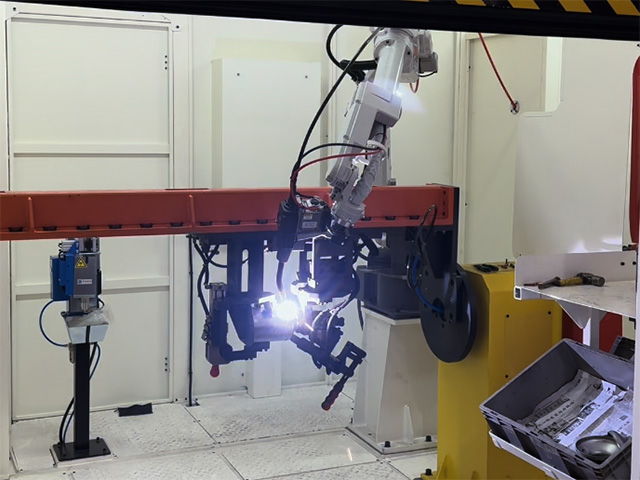

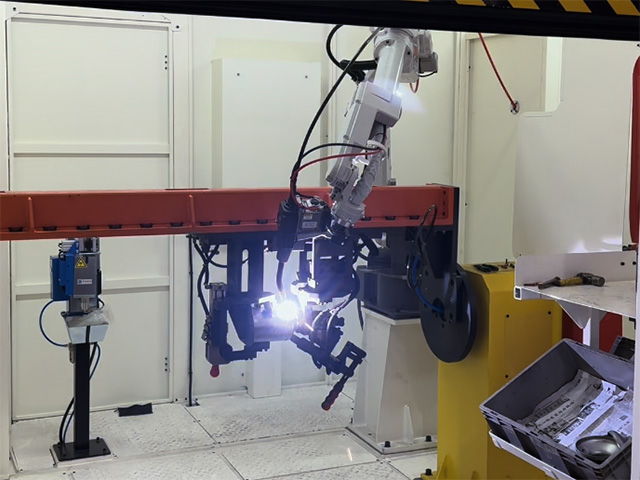

Before diving into drawbacks, it’s important to contextualize their design: Robotic welding systems use programmable 6-axis robots (or fixed automation) to perform welding tasks, guided by CNC controls and sensors. They excel at repetitive, high-volume tasks (e.g., automotive chassis welding) but rely on stable inputs—consistent part geometry, material quality, and environmental conditions—to deliver optimal results. It is precisely this dependence on predictability that gives rise to many of their disadvantages.

1. Prohibitive Initial Investment and Hidden Costs

The most significant barrier to adopting robotic welding is the high upfront cost, which can be prohibitive for small-to-medium enterprises (SMEs):

- A basic robotic welding cell (robot arm + welding torch + controller) starts at $50,000–$100,000; advanced systems (with vision sensors, automated part loading, or safety enclosures) can exceed $300,000.

- Beyond the initial purchase, "hidden costs" often emerge, including:

- Infrastructure modifications: Reinforced flooring to support robot weight, upgraded electrical systems (for high-power lasers or arc welders), and safety barriers (e.g., light curtains) to comply with OSHA standards.

- Software and licensing: Annual fees for programming software updates, CAD/CAM integration tools, or remote monitoring platforms.

- Spare parts: Critical components (e.g., robot motors, welding torches, sensors) have long lead times and high replacement costs (e.g., a robotic welding torch can cost $1,500–$5,000).

For SMEs with limited capital, the return on investment (ROI) timeline can stretch to 3–5 years—far longer than many can afford, especially if production volumes are low.

2. Complex Programming and Specialized Maintenance Requirements

Robotic welding systems are not "plug-and-play"—they demand highly skilled personnel for programming and maintenance, a resource that is often scarce:

- Programming complexity: Creating or modifying weld paths requires expertise in G-code, robot-specific programming languages (e.g., Fanuc Karel, ABB RAPID), and understanding of welding metallurgy (e.g., adjusting parameters for aluminum vs. steel). Even minor changes (e.g., modifying a weld bead size) can take hours of programming time.

- Maintenance challenges: Routine upkeep (e.g., calibrating robot joints, replacing worn wire feeders, cleaning sensors) requires technicians with cross-training in robotics and welding. Without this expertise, systems may operate out of tolerance, producing defective welds, or suffer catastrophic failures (e.g., a misaligned robot arm damaging a $10,000 aerospace component).

The shortage of such skilled workers—exacerbated by the decline in traditional welding vocational programs—means many companies must invest in expensive training (up to $10,000 per employee) or outsource maintenance, adding to long-term costs.

3. Limited Flexibility for Dynamic Production Needs

Robotic welding systems are optimized for repetitive, high-volume tasks—they struggle with the flexibility required for small batches, custom work, or frequent product changes:

- Long setup times: Switching between products (e.g., from welding a car door hinge to a battery tray) requires reprogramming the robot, reconfiguring fixturing (to hold the new part), and testing the weld path. This can take 4–8 hours for complex parts—far longer than the time needed to retrain a human welder.

- Inability to adapt to variability: Unlike human welders, robots cannot adjust to unexpected changes in part geometry (e.g., a slightly warped metal sheet) or material quality (e.g., inconsistent wire feed). Even minor deviations can cause weld defects (e.g., porosity, incomplete fusion) or system shutdowns.

- Poor performance with custom jobs: For one-off or low-volume projects (e.g., custom steel fabrication for architecture), the cost of programming and fixturing often outweighs the efficiency gains of automation. Human welders, by contrast, can adapt to unique designs with minimal setup.

4. Unsuitability for Small Batches and Custom Manufacturing

The economics of robotic welding favor large production runs (10,000+ parts/year). For small batches or custom work, automation becomes cost-inefficient:

- Per-unit cost disparity: For a batch of 100 parts, the fixed costs of programming and fixturing ($5,000–$10,000) are spread across only 100 units, driving up per-unit costs. A human welder, by contrast, has no upfront programming cost and can complete the batch at a lower total cost.

- Fixturing limitations: Custom parts often require custom fixturing (to hold the part during welding), which can cost $1,000–$5,000 per design. For businesses with diverse product lines (e.g., a job shop that makes 50+ custom parts/year), the cost of fixturing alone can render robots unfeasible.

In industries like custom machinery, artisanal metalwork, or prototype manufacturing, manual welding remains the more practical choice.

5. Workforce Displacement and Skill Gaps

Robotic welding automation disrupts traditional workforce dynamics, creating challenges for both employers and employees:

- Job displacement: A single robotic cell can replace 2–3 human welders, leading to layoffs or reduced hours—particularly for low-skilled welders who perform repetitive tasks. This can harm employee morale and create labor relations issues.

- Skill mismatch: While automation creates new roles (robot programmers, maintenance technicians), these positions require technical skills that many existing welders lack. Retraining a 20-year veteran welder to program a robot is time-consuming (6–12 months) and expensive, and not all workers are willing or able to make the shift.

- Loss of tacit knowledge: Human welders develop "tacit expertise" over years—e.g., recognizing when a weld is defective by sound or visual cues—that robots cannot replicate. This knowledge loss can lead to quality control gaps, especially for complex or high-risk welds (e.g., pressure vessels).

6. Technical Limitations with Complex Welds and Environments

Robotic welding systems have inherent technical constraints that limit their use in certain applications:

- Complex geometries: Robots struggle with welds in hard-to-reach areas (e.g., internal cavities of engine blocks) or on parts with extreme curvature (e.g., aerospace turbine blades). Human welders, with their dexterity and spatial awareness, can access these areas more easily.

- Environmental sensitivity: Changes in temperature (e.g., shop floors with unregulated heating/cooling), humidity, or dust can disrupt robot performance. For example, high humidity can cause wire feed issues in MIG welding, while dust can clog sensors—leading to inconsistent welds or system shutdowns.

- Material restrictions: Robots are less adaptable to mixed-material welding (e.g., aluminum to steel) or heat-sensitive materials (e.g., thin stainless steel foils). Human welders can adjust their technique in real time to avoid burn-through or material distortion.

7. Safety Risks and Downtime Vulnerability

While robots improve safety in some ways (reducing human exposure to fumes and heat), they introduce new risks and downtime concerns:

- Safety hazards: Malfunctions (e.g., a robot arm moving outside its programmed path) or programming errors can cause collisions with equipment or workers. Even with safety barriers, a single incident can result in costly damage or injuries.

- Downtime costs: Robotic systems are highly specialized—if a critical component fails (e.g., a robot motor), production halts until the part is replaced. For a high-volume automotive plant, unplanned downtime can cost $10,000–$50,000 per hour. Scheduled maintenance (every 500–1,000 operating hours) also requires downtime, which must be carefully planned to avoid disrupting production.

8. Integration Challenges with Existing Systems

Integrating robotic welding into legacy production lines is often more complex than anticipated:

- Compatibility issues: Older machinery (e.g., manual conveyors, outdated CNC mills) may not communicate with modern robotic systems, requiring expensive upgrades (e.g., adding IoT sensors or new control panels) to enable synchronization.

- Workflow disruptions: Automation often requires reconfiguring production layouts to accommodate robot cells, which can disrupt established workflows and cause temporary productivity losses. For example, a job shop may need to relocate 3–4 manual welding stations to make space for one robotic cell, leading to weeks of reduced output.