In modern manufacturing—from automotive precision components to aerospace-grade alloys and delicate medical devices—welding is no longer just about joining materials: it demands precision, speed, and minimal material distortion to meet increasingly strict quality standards. Laser welding machines have emerged as a transformative solution, but their higher upfront cost raises a critical question for businesses: Are they truly better than traditional welding methods (MIG, TIG, arc welding)? And when does the investment justify the return? This guide evaluates the performance, advantages, costs, and applications of laser welding machines, helping you determine if they align with your industrial needs.

First: What Is Laser Welding, and How Does It Differ From Traditional Methods?

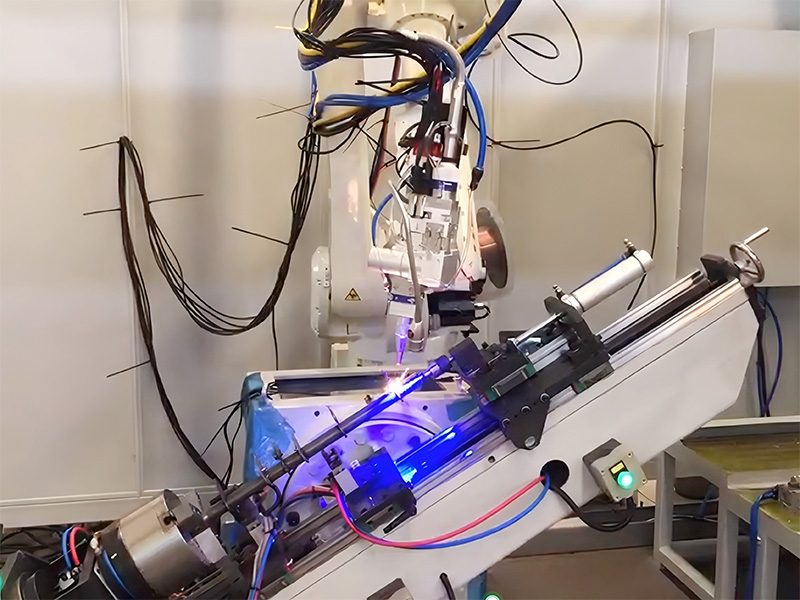

Laser welding is a fusion welding process that uses a highly concentrated, coherent laser beam (generated by fiber, CO₂, or Nd:YAG sources) as the heat source. Unlike traditional methods that rely on an electric arc, flame, or physical contact to melt materials, the laser beam delivers energy with extreme precision—focused to a spot size as small as 0.1 mm. This fundamental difference drives its unique benefits:

| Aspect | Laser Welding | Traditional Welding (MIG/TIG/Arc) |

|-------------------------|------------------------------------------------|---------------------------------------------|

| Heat Input | Low, concentrated (minimal heat-affected zone, HAZ) | High, diffused (large HAZ, risk of distortion) |

| Precision | Sub-millimeter accuracy; ideal for micro-welds | Moderate (mm-scale); challenging for small components |

| Weld Speed | 2–10x faster (e.g., 1 m/min for automotive body panels) | Slower (e.g., 0.1–0.5 m/min for TIG) |

| Material Distortion | Minimal (HAZ width <0.5 mm) | Significant (HAZ width 2–5 mm); requires post-weld straightening |

| Versatility | Welds metals, plastics, ceramics; handles reflective/heat-sensitive materials | Limited to metals; struggles with reflective alloys (e.g., aluminum, copper) |

Are

Laser Welding Machines "Good"? Key Advantages That Justify Their Use

Laser welding machines excel in scenarios where traditional methods fall short—delivering tangible value that often offsets their higher cost:

1. Unmatched Precision for Micro-Scale and High-Tolerance Welds

The laser beam’s narrow focus (0.1–1 mm spot size) enables welds in tight spaces and on delicate components that traditional methods cannot handle:

- Electronics: Welding microchips, sensor leads, or battery tabs (where a 0.5 mm error would ruin the component).

- Medical Devices: Joining surgical instrument parts (e.g., 1 mm-thick stainless steel scalpel blades) or implantable components (e.g., titanium hip stems) without compromising biocompatibility.

- Jewelry: Repairing intricate gold or platinum pieces (e.g., diamond settings) without melting surrounding details—a task TIG welding would fail at.

For example, a medical device manufacturer using laser welding can produce 0.3 mm-diameter welds on catheter tubes with 99.9% consistency, vs. 5–10% rejection rates with TIG welding.

2. Faster Production and Higher Throughput

The concentrated laser beam melts material quickly, reducing weld cycle times by 200–1,000% compared to traditional methods:

- Automotive: Laser welding of car body seams (e.g., aluminum door frames) takes 10 seconds per joint, vs. 60 seconds with MIG welding—cutting assembly line time by 80%.

- Aerospace: Welding turbine blade edges (titanium alloy) at 0.8 m/min, vs. 0.2 m/min with TIG—enabling 4x higher daily production.

This speed translates to lower labor costs, faster time-to-market, and the ability to scale production without adding extra shifts.

3. Superior Weld Quality and Durability

Laser welding produces welds with:

- Higher Strength: Narrow, deep weld profiles (depth-to-width ratio up to 10:1) create stronger joints than the shallow, wide welds of MIG/TIG. For example, laser-welded aluminum joints have 15–20% higher tensile strength than TIG-welded equivalents.

- Minimal Defects: No spatter (common in MIG) or porosity (common in arc welding), reducing post-weld inspection and rework.

- Cleaner Finish: No flux or filler material residue (in autogenous laser welding), eliminating the need for post-weld cleaning—critical for semiconductor or food-processing equipment.

4. Versatility Across Materials and Applications

Laser welding machines handle a broader range of materials than traditional methods, including:

- Reflective Metals: Aluminum, copper, and brass (traditional TIG struggles with these due to heat reflection).

- Heat-Sensitive Materials: Plastics (e.g., medical-grade PVC) and thin metals (e.g., 0.1 mm stainless steel foils) that would warp under TIG/arc heat.

- Dissimilar Materials: Joining aluminum to steel (used in automotive lightweighting) or titanium to nickel alloys (aerospace components)—a challenge for most traditional methods.

5. Reduced Material Waste and Post-Processing

The small HAZ and precise heat control minimize material distortion, eliminating the need for:

- Post-weld grinding, straightening, or machining (saves 15–30% of total production costs).

- Scrap from damaged components (e.g., a laser-welded electronics part has <1% scrap rate, vs. 5–8% with TIG).

For high-value materials (e.g., titanium, gold), this waste reduction alone can save thousands of dollars annually.

When Might Laser Welding Machines Not Be the Best Choice?

While laser welding offers significant benefits, it is not a one-size-fits-all solution. It may be less ideal for:

- Thick Material Welding (>20 mm): High-power laser machines (10+ kW) can handle this, but they are costly; traditional arc welding is more economical for thick steel plates (e.g., construction beams).

- Low-Volume, Low-Precision Work: For simple tasks (e.g., welding 10 mm steel brackets in a small workshop), the $5,000–$10,000 cost of a basic MIG machine is more practical than a $50,000+ laser system.

- High-Impurity Materials: Dirty or rusted metals require pre-cleaning (laser beams are scattered by contaminants), whereas MIG can tolerate minor surface imperfections.

Key Factors to Evaluate Before Investing

To determine if a laser welding machine is "good" for your business, consider these criteria:

1. Application Requirements

- Precision Needs: If your work demands sub-millimeter accuracy (e.g., medical devices, electronics), laser welding is non-negotiable.

- Material Type/Thickness: For thin, reflective, or dissimilar materials, laser welding is superior; for thick, low-tolerance metals, traditional methods may suffice.

2. Cost-Benefit Analysis

- Upfront Cost: Laser machines range from $20,000 (handheld fiber lasers for small shops) to $500,000+ (high-power industrial systems).

- Long-Term Savings: Calculate savings from faster production, reduced waste, and lower post-processing costs. Most manufacturers recoup their investment within 1–3 years for high-volume operations.

3. Machine Type Selection

Choose the laser source based on your material:

- Fiber Lasers: Best for metals (steel, aluminum, copper); cost-effective, high efficiency (80–90% energy conversion).

- CO₂ Lasers: Ideal for non-metals (plastics, ceramics); used in packaging and textile welding.

- Nd:YAG Lasers: Suitable for reflective metals and pulsed welding (e.g., jewelry repair); higher cost but versatile.