Remote laser welding (RLW) has emerged as a transformative joining technology in industrial manufacturing, revolutionizing material assembly through its non-contact operation, exceptional precision, and superior efficiency. Unlike traditional welding methods (e.g., arc welding, resistance welding), RLW utilizes a highly focused laser beam to fuse materials—eliminating physical contact with workpieces, minimizing process-induced defects, and enabling unprecedented control over the welding zone. This technology has become indispensable across high-precision and high-volume industries, where it addresses critical challenges such as heat distortion, complex geometry processing, and quality consistency.

Remote laser welding is a non-contact thermal joining process that employs a collimated, high-energy laser beam to melt and fuse compatible materials (metals, polymers, or composites). The laser beam is typically delivered via fiber optics or articulated mirror systems, which provide exceptional flexibility to access hard-to-reach weld zones without repositioning the workpiece.

Core Operational Characteristics

- Non-contact operation: Eliminates tool wear, workpiece deformation from mechanical pressure, and contamination risks.

- High spatiotemporal precision: Achieves weld seam widths as narrow as 0.1 mm and processing speeds up to 10 m/min, outperforming traditional methods.

- Minimal heat-affected zone (HAZ): Concentrated laser energy reduces thermal distortion—critical for thin-walled components or heat-sensitive materials (e.g., titanium alloys, polymers).

- Material versatility: Compatible with ferrous metals (steel, stainless steel), non-ferrous metals (aluminum, copper), and engineering plastics (polyamide, polycarbonate).

2. Key Advantages of Remote Laser Welding

RLW’s technical attributes translate to tangible operational and economic benefits for manufacturers, making it a preferred solution for demanding applications:

| Advantage | Technical Rationale | Industrial Impact |

|-----------|---------------------|--------------------|

| High process efficiency | Rapid beam positioning (via galvanometric scanners) and continuous/pulsed laser modes enable high-volume production. | Reduces cycle time by 30–50% compared to traditional welding in automotive/aerospace mass production. |

| Reduced fixturing requirements | Flexible beam delivery eliminates the need for complex, part-specific fixtures to reposition workpieces. | Lowers tooling costs by 20–40% and enables quick changeovers for product variants. |

| Superior weld quality | Narrow HAZ and precise energy control minimize porosity, cracking, and residual stress in welds. | Improves product durability and reduces post-weld inspection/rework rates. |

| Seamless automation integration | Compatible with robotic arms, CNC systems, and vision-guided positioning for unmanned operation. | Enhances process consistency (defect rates < 0.1% in optimized setups) and reduces manual labor dependence. |

3. Essential Equipment and Core Technologies

The performance of RLW depends on the synergy of three critical component systems, each engineered for precision and reliability:

3.1 Laser Sources

The choice of laser source determines energy density, wavelength, and pulse characteristics—key factors for material compatibility:

- Fiber lasers: Dominant in industrial RLW (wavelength: 1060–1080 nm). High electrical-to-optical efficiency (> 30%), excellent beam quality (M² < 1.1), and suitability for metals (especially aluminum and copper).

- Diode-pumped solid-state (DPSS) lasers: Used for high-precision micro-welding (e.g., electronics). Wavelengths (532 nm, 1064 nm) enable absorption in heat-sensitive materials.

- CO₂ lasers: Primarily for polymer welding (wavelength: 10.6 μm), as polymers absorb mid-infrared radiation efficiently.

3.2 Beam Delivery Systems

Responsible for guiding and focusing the laser beam to the weld zone:

- Fiber optic delivery: Ideal for long-distance beam (up to 100 m) and integration with robotic arms. Enables consistent beam quality across complex trajectories.

- Galvanometric scanner systems: Uses high-speed mirrors to position the laser beam (up to 5 m/s) without moving the workpiece. Critical for 2D/3D contour welding.

- Articulated arm systems: Combines mirrors and mechanical arms for access to confined spaces (e.g., aerospace engine components).

3.3 Control and Monitoring Units

Ensure real-time process optimization and quality assurance:

- CNC controllers: Precisely synchronize beam positioning, laser power, and travel speed with workpiece geometry (via CAD/CAM integration).

- In-process monitoring systems: Utilize high-speed cameras, pyrometers, or coherent imaging to detect weld defects (porosity, misalignment) in real time. Enables closed-loop adjustments to laser parameters.

- Software platforms: Support path planning, parameter libraries for different materials, and data logging for compliance (critical in medical/aerospace industries).

4. Industrial Applications by Sector

4.1 Automotive Industry

RLW is a cornerstone of modern automotive manufacturing, addressing the industry’s needs for lightweighting, high-volume production, and structural integrity:

- Body-in-white (BIW) assembly: Welds high-strength steel (HSS) and aluminum alloy panels with minimal distortion. Enables multi-layer welds (e.g., 3–5 sheets of steel) in hard-to-reach areas (e.g., door frames, roof rails).

- Chassis and powertrain components: Joins titanium or magnesium alloy parts (e.g., suspension brackets, gearbox housings) with high fatigue resistance.

- Battery pack manufacturing: Welds copper-aluminum tabs in electric vehicle (EV) batteries—fiber lasers’ high energy density overcomes the challenges of dissimilar metal welding (e.g., high thermal conductivity of copper).

Impact: Reduces vehicle weight by 5–10% (enhancing fuel/EV efficiency) and cuts BIW production time by 25%.

4.2 Aerospace and Defense

The aerospace industry demands welds that meet strict safety standards (e.g., ASTM F3125) and withstand extreme conditions (temperature, pressure, vibration). RLW delivers on these requirements:

- Airframe components: Welds titanium and nickel-based superalloy (e.g., Inconel) structures (e.g., wing spars, fuselage frames) with minimal HAZ—critical for maintaining material strength at high altitudes.

- Engine parts: Repairs and manufactures turbine blades and combustion chambers using pulsed laser welding to avoid thermal damage to precision-machined surfaces.

- Defense applications: Welds armor plates (e.g., ceramic-reinforced steel) and missile components with high penetration depth and structural uniformity.

4.3 Electronics and Micro-Manufacturing

Miniaturization in electronics requires micro-welds (≤ 0.5 mm) with zero thermal damage to adjacent components. RLW is the primary technology for this niche:

- Printed circuit boards (PCBs): Welds copper traces and component leads (e.g., resistors, capacitors) without damaging delicate solder masks or semiconductor chips.

- Microelectronic assemblies: Joins gold, silver, or copper wires (25–100 μm diameter) in sensors, microchips, and wearable devices.

- EV battery cells: Welds thin foils (5–20 μm) in prismatic or cylindrical battery cells, ensuring low electrical resistance and long cycle life.

4.4 Medical Device Manufacturing

Medical devices require ultra-precise, contamination-free welds to meet regulatory standards (e.g., FDA 21 CFR Part 820). RLW’s non-contact operation and micro-welding capabilities make it ideal:

- Implantable devices: Welds titanium or cobalt-chromium alloy components in pacemakers, hip implants, and spinal fusion devices. The narrow HAZ preserves biocompatibility and corrosion resistance.

- Surgical instruments: Joins stainless steel parts (e.g., forceps, scalpels) with smooth, burr-free welds to avoid tissue irritation.

- Diagnostic equipment: Welds microfluidic chips and sensor housings (e.g., glucose monitors) with leak-tight seams (≤ 1 μm tolerance).

4.5 3D Laser Welding for Complex Geometries

3D RLW—integrated with 3D vision systems and robotic arms—enables welding of irregular, three-dimensional components that are impossible to process with traditional methods:

- Automotive: Welds curved aluminum roof panels and complex BIW joints (e.g., A-pillars).

- Aerospace: Manufactures lattice structures (used in aircraft interiors) and 3D-printed titanium components (e.g., engine brackets).

- Medical: Produces customized orthopedic implants (e.g., knee prostheses) with patient-specific contours.

5. Integration with Automation and Industry 4.0

RLW is a core technology in smart manufacturing, enabling data-driven, adaptive production lines aligned with Industry 4.0 principles:

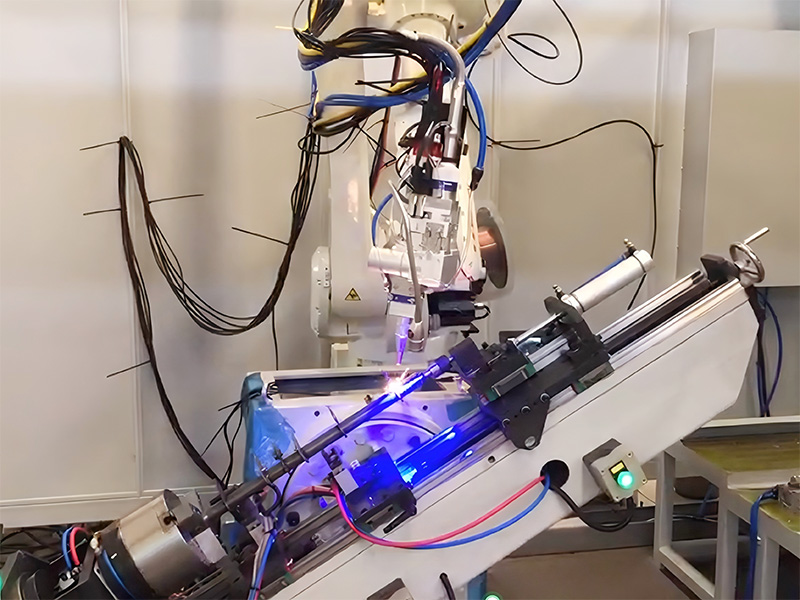

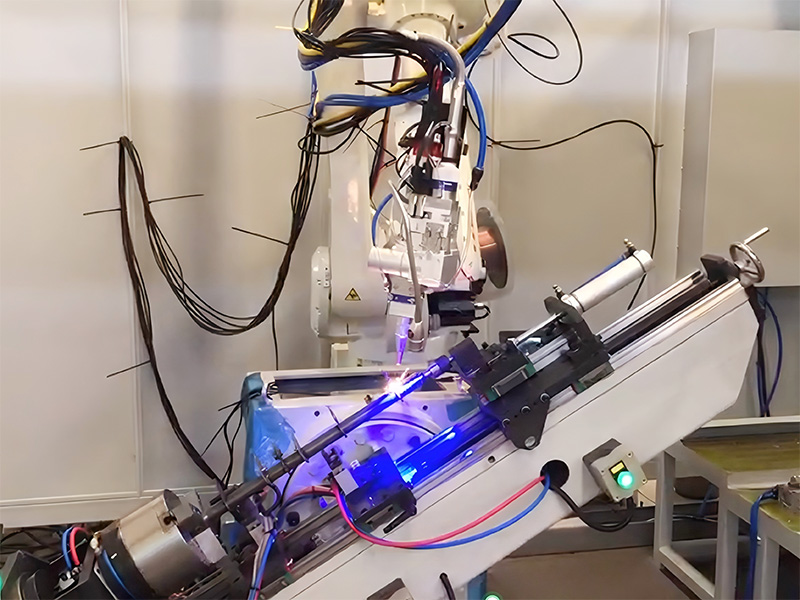

- Robotic integration: Collaborative robots (cobots) and industrial robots equipped with RLW heads perform high-precision welds in dynamic environments (e.g., mixed-model automotive lines).

- Digital twin integration: Virtual models of the welding process simulate beam paths, energy distribution, and HAZ to optimize parameters before physical production—reducing trial-and-error costs by 30–40%.

- IoT-enabled monitoring: Sensors embedded in RLW systems collect real-time data (laser power, beam position, weld temperature) and transmit it to cloud platforms for analytics. This enables predictive maintenance (reducing downtime by 20%) and compliance tracking.

6. Future Trends and Innovations

The evolution of RLW is driven by advancements in laser technology, artificial intelligence (AI), and material science. Key trends include:

- High-power fiber lasers: Next-generation fiber lasers (15–30 kW) will enable faster welding of thick materials (e.g., 20–50 mm steel plates) for heavy industry (construction, shipbuilding).

- AI-driven process control: Machine learning algorithms will analyze in-process data to autonomously adjust laser parameters (power, speed, focus) in real time—further reducing defect rates and optimizing energy use.

- Green laser welding: Green lasers (532 nm) will improve absorption in highly reflective materials (e.g., copper, brass), expanding RLW’s application in EV batteries and electronics.

- Hybrid RLW systems: Combining RLW with additive manufacturing (AM) will enable “weld-and-build” processes for complex components—critical for aerospace and medical innovation.