In the era of advanced manufacturing and Industry 4.0, the pursuit of precision engineering, complex component fabrication, and operational efficiency has driven the rapid adoption of multi-axis laser cutting technologies. Among these, the 5-axis laser cutting machine stands as a pinnacle of technological innovation, redefining the boundaries of material processing across high-precision sectors. Unlike conventional 2D/3D laser cutters limited by linear motion, 5-axis systems integrate three linear axes (X, Y, Z) with two rotational axes (typically A and B, or A and C), enabling simultaneous multi-directional movement of the laser cutting head relative to the workpiece. This kinematic flexibility empowers manufacturers to tackle intricate 3D geometries, asymmetric contours, and beveled edges that were previously unachievable or cost-prohibitive with traditional cutting methods.

This article provides a technical deep dive into the core advantages of 5-axis

laser cutting machines, emphasizing their technological uniqueness, quantifiable performance benefits, and industry-specific value propositions. Designed for manufacturing engineers, production managers, and technology procurement professionals, this analysis equips stakeholders with actionable insights to evaluate the strategic impact of adopting this advanced cutting solution.

Core Technical Definition of 5-Axis Laser Cutting Machines

To contextualize their advantages, it is critical to first clarify the technical configuration of 5-axis laser cutting systems:

- Linear Axes (X, Y, Z): Enable translation along the horizontal (X), transverse (Y), and vertical (Z) planes, providing basic positional control of the cutting head.

- Rotational Axes (A, B/C): The A-axis typically rotates the workpiece or cutting head around the X-axis (tilting), while the B/C-axis rotates around the Y/Z-axis (swiveling), with angular travel ranges of ±90° to ±120° depending on the system design.

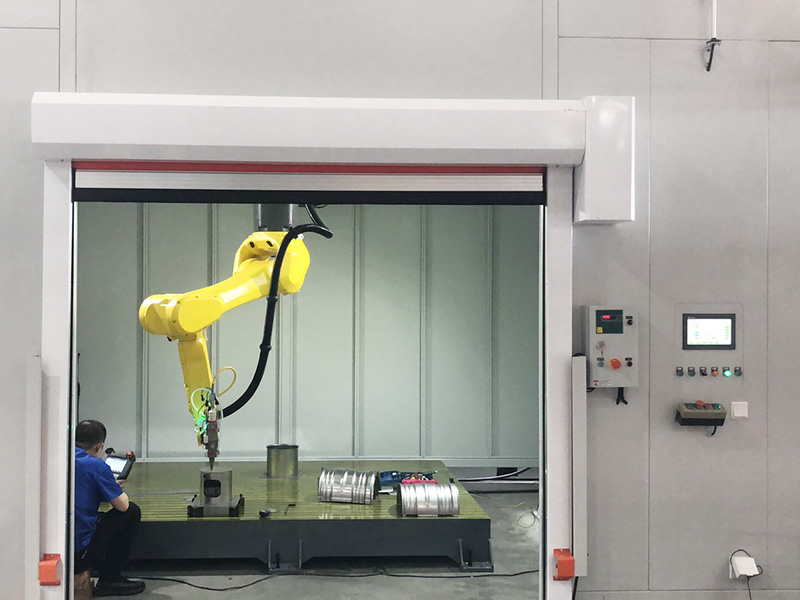

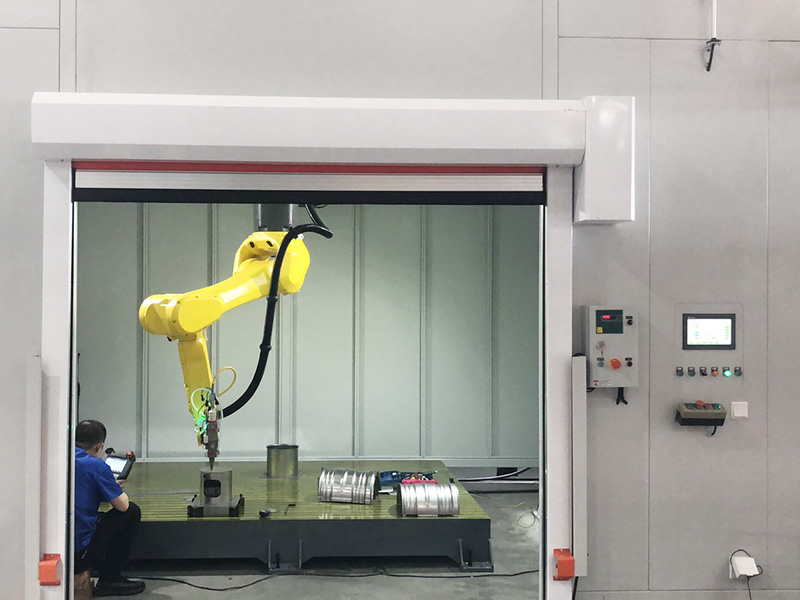

- Synchronized Kinematics: Advanced CNC controllers (e.g., Siemens Sinumerik, Fanuc 31i-B5) coordinate all five axes in real time, ensuring precise trajectory control even during high-speed cutting of complex 3D surfaces.

- Laser Source Compatibility: Most 5-axis systems integrate fiber lasers (1–15 kW) for metal processing, with CO₂ lasers (1–6 kW) optional for non-metallic materials, leveraging beam quality parameters (M² < 1.1 for fiber lasers) to maintain cutting precision across all axis orientations.

Key Advantages of 5-Axis Laser Cutting Machines

1. Unparalleled Precision and Dimensional Accuracy for Complex Geometries

5-axis laser cutting machines deliver industry-leading precision that addresses the most stringent tolerance requirements in high-criticality applications:

- Positional Accuracy: Achieves dimensional tolerances of ±0.01–±0.05 mm and repeatability of ±0.005–±0.02 mm, outperforming 3-axis systems (typically ±0.1 mm tolerance) by a factor of 2–5. This is critical for aerospace components (e.g., turbine blades, aircraft fuselage panels) and medical implants (e.g., titanium bone plates) where even micro-deviations can compromise performance.

- Minimized Thermal Distortion: The ability to orient the laser beam perpendicular to the cutting surface at all points reduces heat accumulation, limiting the heat-affected zone (HAZ) to <0.1 mm for thin materials (≤3 mm) and <0.5 mm for thick metals (≤20 mm). This preserves material integrity and eliminates the need for post-processing (e.g., grinding, deburring) common with 3-axis cutting.

- Consistent Bevel Cutting: Enables precise bevel angles (0–60°) and compound bevels across complex contours, eliminating the need for secondary machining operations. For example, in automotive exhaust systems, 5-axis cutting produces weld-ready beveled edges with a single pass, reducing cycle time by 40–60% compared to 3-axis cutting followed by milling.

- Reduced Material Waste: High-precision path planning and nest optimization software minimize kerf loss (kerf width as narrow as 0.1 mm for fiber lasers) and material scrap, reducing waste rates from 10–15% (3-axis systems) to 3–5% in mass production.

2. Versatility in Processing Complex 3D Geometries and Multi-Material Compatibility

The kinematic flexibility of 5-axis systems unlocks unprecedented versatility in handling diverse workpiece shapes and material types:

- 3D Contour Cutting: Capable of processing asymmetric components, undercuts, curved surfaces, and free-form geometries (e.g., aerospace engine casings, automotive body-in-white structures) without repositioning the workpiece. This eliminates the need for custom fixtures and multiple setups, reducing lead time for complex parts by 30–50%.

- Broad Material Compatibility: Efficiently processes a wide range of materials, including:

- Metals: Carbon steel (0.1–30 mm), stainless steel (0.1–25 mm), aluminum alloys (0.5–20 mm), titanium (0.5–15 mm), and high-strength alloys (Inconel, Hastelloy) used in extreme environments.

- Composites: Carbon fiber-reinforced polymers (CFRP), glass fiber-reinforced polymers (GFRP), and aramid fiber composites, with laser parameters optimized to prevent delamination and fiber damage.

- Non-Metals: Engineering plastics (PC, ABS, PEEK), ceramics, and wood-based materials (for specialized industrial applications), leveraging CO₂ laser sources for precise ablation.

- Low-Volume, High-Variety Production: Rapid programming via CAD/CAM integration (e.g., SolidWorks, AutoCAD) and offline simulation tools enables quick changeovers between product variants, making 5-axis systems ideal for custom fabrication, prototyping, and small-batch production (10–1,000 units).

3. Enhanced Operational Efficiency and Throughput

5-axis laser cutting machines deliver quantifiable efficiency gains that directly impact production scalability and cost-effectiveness:

- Reduced Setup and Cycle Times: Eliminates multiple workpiece repositioning and fixture changes (common with 3-axis systems), reducing setup time per part from hours to minutes. For example, a 5-axis system can complete a complex aerospace component in 1–2 hours, compared to 4–6 hours with 3-axis cutting and secondary operations.

- High Cutting Speeds: Fiber laser-powered 5-axis systems achieve cutting speeds of 3–5 m/min for 10 mm stainless steel and 5–8 m/min for 3 mm aluminum, outperforming 3-axis systems by 20–30% while maintaining precision. High-power models (10–15 kW) further increase throughput for thick materials.

- Automation Integration: Seamlessly integrates with automated material handling systems (conveyors, robotic loaders/unloaders), machine vision for part alignment, and manufacturing execution systems (MES) for real-time production monitoring. This enables lights-out manufacturing, 24/7 operation, and throughput increases of 50–100% in high-volume environments.

- Reduced Labor Requirements: Automated path planning, real-time process monitoring, and self-diagnostic features minimize operator intervention, reducing labor costs by 40–70% compared to manual or semi-automated cutting processes.

4. Superior Part Quality and Reduced Post-Processing

The precision and controlled cutting environment of 5-axis laser systems deliver finished parts with exceptional surface quality and structural integrity:

- Smooth Cut Edges: Produces edge finishes with Ra values of 0.8–3.2 μm, eliminating the need for grinding, sanding, or deburring in most applications. This is critical for medical devices and aerospace components where surface roughness can impact biocompatibility or aerodynamic performance.

- Eliminated Secondary Machining: Bevel cutting, hole drilling, and contouring are completed in a single setup, eliminating the need for secondary operations (e.g., milling, drilling, welding preparation). This reduces lead time, lowers production costs, and minimizes the risk of dimensional errors from multiple handling steps.

- Consistent Quality in Mass Production: Advanced process control features (e.g., adaptive laser power adjustment, focus position monitoring) ensure uniform cut quality across thousands of parts, reducing defect rates to <0.1%—a significant improvement over 3-axis systems (1–3% defect rates) and manual cutting (5–10% defect rates).

5. Enhanced Safety and Operational Reliability

Modern 5-axis laser cutting machines incorporate advanced safety features and robust design elements to ensure workplace safety and long-term operational stability:

- Laser Safety Compliance: Meets international safety standards (EN 60825, ANSI Z136.1) with enclosed cutting chambers, interlocked access doors, and laser safety curtains (Class 4 laser protection). Real-time laser power monitoring and automatic shutdown systems prevent accidental exposure.

- Process Stability: Rigid machine frames (cast iron or welded steel) with vibration damping technology minimize deflection during high-speed cutting, ensuring consistent precision over extended operation. Servo-driven axes with high-resolution encoders (1 μm resolution) enhance motion control reliability.

- Predictive Maintenance Capabilities: Integrated IoT sensors monitor key components (laser source, cutting head, servo motors) for wear and performance degradation. Predictive maintenance software (e.g., Trumpf Condition Monitoring, Bystronic ByVision) alerts operators to potential issues, reducing unplanned downtime by 25–40%.

6. Long-Term Cost-Effectiveness and ROI

While the initial capital investment for 5-axis laser cutting machines (typically $300,000–$1.5 million) is higher than 3-axis systems ($100,000–$500,000), the long-term economic benefits deliver compelling ROI:

- Reduced Total Cost of Ownership (TCO): Lower labor costs, minimized material waste, and eliminated secondary operations reduce TCO by 20–30% over a 5-year lifespan.

- Fast ROI: High-volume manufacturers typically achieve ROI within 1.5–3 years, while specialized sectors (aerospace, medical) with high-margin components may see ROI in as little as 1 year.

- Energy Efficiency: Fiber laser 5-axis systems consume 25–30% less energy than CO₂-based 3-axis systems, with electrical-to-optical conversion efficiencies of 25–30% (vs. 10–15% for CO₂ lasers), reducing operational energy costs.

- Asset Longevity: Laser sources (fiber lasers) have a lifespan of 100,000 operating hours (vs. 20,000–30,000 hours for CO₂ lasers), minimizing replacement costs and downtime.

Industry-Specific Applications and Value Propositions

5-axis laser cutting machines are tailored to address the unique challenges of high-precision industries:

- Aerospace: Fabrication of turbine blades, engine casings, wing ribs, and composite components with tight tolerances (±0.02 mm) and complex 3D geometries. Reduces weight of aircraft components by optimizing material usage, improving fuel efficiency.

- Automotive: Production of body-in-white structures, exhaust systems, suspension components, and electric vehicle (EV) battery enclosures. Enables lightweighting with high-strength aluminum and advanced steels, reducing vehicle weight by 10–15%.

- Medical Devices: Cutting of surgical instruments, implantable components (titanium hip implants, stainless steel stents), and 3D-printed part finishing. Ensures biocompatibility via smooth edges and minimal material contamination.

- Tool and Die Making: Fabrication of complex dies, molds, and fixtures with precise cavities and beveled edges. Reduces tool production time by 40–60% compared to traditional machining.

- Renewable Energy: Cutting of wind turbine components (gearbox parts, rotor blades), solar panel frames, and hydrogen fuel cell bipolar plates. Enables efficient processing of large, thick-walled components.