To contextualize the suitability of materials for laser cutting, it is first critical to establish the technical fundamentals of the process. Laser cutting—an advanced thermal ablation technology employed in Computer Numerical Control (CNC) laser cutting systems—utilizes a coherent, monochromatic laser beam (focused via optical lenses to achieve energy densities of 10^6–10^8 W/cm²) to induce material transformation through melting, vaporization, or oxidative degradation. The efficacy of laser cutting is inherently dependent on the material’s optical properties (absorptivity at the laser wavelength), thermal characteristics (thermal conductivity, melting point, specific heat capacity), and chemical composition. Three primary laser types dominate industrial applications: fiber lasers (1064 nm wavelength, optimal for metals), CO₂ lasers (10.6 μm wavelength, ideal for non-metals), and Nd:YAG lasers (1064 nm, versatile for both metals and ceramics). The non-contact nature of the process minimizes mechanical stress, ensuring minimal material deformation, narrow kerf widths (0.1–0.5 mm for precision applications), and high dimensional accuracy (±0.01–±0.1 mm), making it indispensable across aerospace, automotive, electronics, and advanced manufacturing sectors.

Laser cutting’s ascendancy stems from its unique confluence of precision, throughput, and design flexibility—capabilities that outperform traditional subtractive methods (e.g., mechanical cutting, waterjet) for complex geometries and tight tolerances. Its ability to process both rigid and flexible materials, coupled with minimal tool wear and automated path planning via CAD/CAM integration, has solidified its role as a cornerstone of Industry 4.0 manufacturing. Below is a technical breakdown of materials compatible with laser cutting, including their processing characteristics, optimal laser parameters, and industrial applications.

1. Metallic Materials: Ferrous and Non-Ferrous Alloys

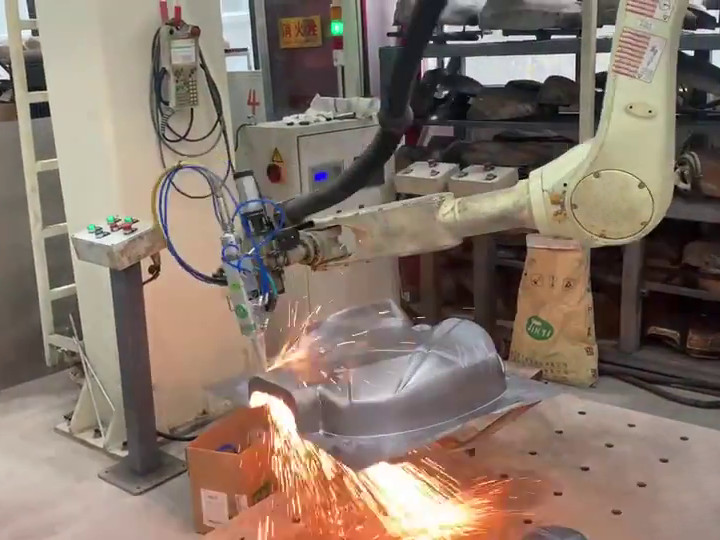

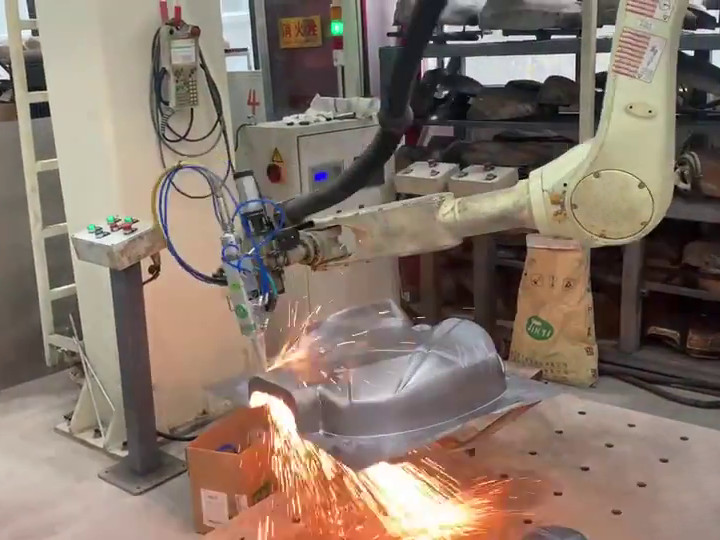

Metals represent the most widely processed category in industrial laser cutting, leveraging fiber lasers (1–15 kW) or Nd:YAG lasers for their high absorption at near-infrared (NIR) wavelengths. The key determinants of laser cuttability for metals include low reflectivity (to minimize beam energy loss), moderate thermal conductivity (to concentrate heat at the cutting interface), and stable oxidation behavior (to facilitate melt expulsion via assist gases such as oxygen or nitrogen).

1.1 Ferrous Metals

- Carbon Steel: A staple in construction, automotive, and heavy machinery, carbon steel (C-content 0.1–1.5%) exhibits excellent laser cuttability. For low-carbon steel (≤0.2% C), fiber lasers (3–6 kW) achieve cutting speeds of 1–5 m/min for 1–10 mm thicknesses, with oxygen assist gas enhancing cutting efficiency via exothermic oxidation. High-carbon steel (≥0.8% C) requires lower cutting speeds (0.3–1.5 m/min for 10 mm) to mitigate heat-affected zone (HAZ) cracking, typically using nitrogen assist gas for oxide-free edges. Kerf width ranges from 0.2–0.4 mm, and post-processing (e.g., deburring) is minimal for precision applications.

- Stainless Steel: Austenitic stainless steel (304, 316 grades) is favored for its corrosion resistance and strength, making it ideal for aerospace components, food processing equipment, and medical devices. Its higher chromium content increases reflectivity, necessitating fiber lasers (6–12 kW) for thicknesses up to 25 mm. Nitrogen assist gas (pressure 10–20 bar) is critical to prevent oxidation and achieve clean, passive edges with Ra < 1.6 μm. Cutting speeds range from 2–8 m/min for 1–5 mm thicknesses, with HAZ widths < 0.3 mm.

- Tool Steel: High-hardness tool steels (e.g., H13, D2) require pulsed fiber lasers (1–3 kW, pulse frequency 1–10 kHz) to minimize thermal distortion. Used in die and mold manufacturing, these materials are typically processed at thicknesses ≤10 mm, with cutting speeds of 0.1–0.5 m/min and nitrogen assist gas to preserve hardness.

1.2 Non-Ferrous Metals

- Aluminum Alloys: Lightweight (density 2.7 g/cm³) and corrosion-resistant, aluminum (6061, 7075 grades) is critical in aerospace, EV battery enclosures, and consumer electronics. Its high thermal conductivity (237 W/m·K) and reflectivity (≥80% at 1064 nm) demand high-power fiber lasers (8–15 kW) and high cutting speeds (3–10 m/min for 1–5 mm) to concentrate heat before dissipation. Nitrogen assist gas (20–30 bar) prevents oxide formation, while pulsed laser modes reduce HAZ to <0.2 mm. Thickness limits for practical cutting are ~20 mm.

- Copper and Brass: These high-conductivity metals (copper: 401 W/m·K; brass: 110 W/m·K) pose significant challenges due to high reflectivity (≥90% at NIR wavelengths). Pulsed fiber lasers (5–10 kW, pulse duration 1–10 μs) or green lasers (532 nm, higher absorption) are required to achieve clean cuts. Copper (C11000) is processed at thicknesses ≤10 mm (speed 0.5–2 m/min for 3 mm), while brass (C26000) can be cut up to 15 mm with similar parameters. Nitrogen assist gas is mandatory to avoid tarnishing and ensure edge quality. Applications include electrical components, heat exchangers, and decorative hardware.

- Titanium Alloys: Used in aerospace (engine blades, fuselage components) and medical implants, titanium (Ti-6Al-4V) offers high strength-to-weight ratio and biocompatibility. Its moderate thermal conductivity (16 W/m·K) and high melting point (1668°C) require fiber lasers (4–8 kW) with argon assist gas (inert atmosphere to prevent oxidation). Cutting speeds range from 0.3–1.5 m/min for 1–8 mm thicknesses, with HAZ widths <0.1 mm—critical for preserving mechanical properties.

2. Polymeric Materials: Thermoplastics and Thermosets

Polymers are ideally suited for CO₂ laser cutting (10.6 μm wavelength), as their organic molecular structures absorb mid-infrared radiation efficiently, leading to clean, vaporization-driven cuts with minimal melting. Key considerations include thermal stability (to avoid toxic fume emission) and melt viscosity (to prevent edge burring).

2.1 Commonly Processed Plastics

- Acrylic (PMMA): A transparent thermoplastic (transmittance ≥92% for visible light) with excellent laser cuttability. CO₂ lasers (30–150 W) achieve cutting speeds of 0.5–3 m/min for 1–10 mm thicknesses, producing flame-polished edges (Ra < 0.8 μm) without post-processing. Used in signage, architectural glazing, and optical components, acrylic’s low water absorption (<0.3%) ensures dimensional stability during cutting.

- Polycarbonate (PC): Impact-resistant (Izod impact strength 650 J/m) and flame-retardant, PC is critical for safety equipment (face shields, riot gear), automotive lighting, and electronic enclosures. CO₂ lasers (50–200 W) cut PC at 0.3–1.5 m/min for 1–12 mm thicknesses, though care is required to avoid thermal degradation (use low power density: 10–20 W/mm²). Nitrogen assist gas prevents yellowing, and edges may require light sanding for transparency.

- Polyethylene (PE) and Polypropylene (PP): Low-density (PE: 0.91–0.94 g/cm³; PP: 0.90 g/cm³) thermoplastics with excellent chemical resistance. CO₂ lasers (30–100 W) cut these materials at 1–5 m/min for 1–8 mm thicknesses, leveraging their low melting points (PE: 110–130°C; PP: 160–170°C). Used in packaging, chemical tanks, and medical device components, PE/PP require minimal assist gas (air) but may exhibit slight edge burring for thick sections.

- Polyamide (Nylon): A durable, wear-resistant thermoplastic used in gears, bearings, and 3D-printed part finishing. CO₂ lasers (50–150 W) cut nylon at 0.5–2 m/min for 1–6 mm thicknesses, with nitrogen assist gas to prevent oxidation and fiber fraying. Its high moisture absorption (1–2%) necessitates pre-drying (80°C for 4–6 hours) to avoid porosity in cuts.

2.2 Materials to Avoid

- Polyvinyl Chloride (PVC): Releases toxic hydrogen chloride (HCl) gas during laser cutting, posing health risks and corroding equipment.

- Polyurethane (PUR): Emits toxic isocyanates and exhibits excessive melting, leading to poor edge quality.

3. Wooden Materials: Natural and Engineered Woods

Wood and wood-based composites are compatible with CO₂ lasers (40–150 W), which vaporize lignin and cellulose while minimizing splintering. Cuttability depends on moisture content (optimal: 6–12%), density, and grain orientation—with engineered woods offering superior consistency due to uniform composition.

- Plywood: A layered composite (3–12 plies) with balanced strength and flexibility. CO₂ lasers cut plywood at 0.3–2 m/min for 3–18 mm thicknesses, producing clean edges without delamination when using moderate power (60–100 W). Used in furniture, architectural models, and packaging, plywood’s grain direction has minimal impact on cut quality compared to solid wood.

- Medium-Density Fiberboard (MDF): A homogeneous engineered wood (density 700–800 kg/m³) ideal for intricate engraving and cutting. CO₂ lasers (80–150 W) achieve cutting speeds of 0.2–1.5 m/min for 3–25 mm thicknesses, with smooth, chip-free edges. MDF’s low moisture content (<8%) and uniform density make it a top choice for custom signage, cabinetry, and decorative panels.

- Solid Wood: Hardwoods (birch, cherry, maple) and softwoods (pine, cedar) are processed with CO₂ lasers (40–100 W). Hardwoods (density 600–900 kg/m³) require slower speeds (0.1–0.8 m/min for 3–10 mm) to avoid burning, while softwoods (300–500 kg/m³) cut faster (0.5–2 m/min) but may exhibit grain-induced edge irregularities. Used in high-end furniture, musical instruments, and artisanal crafts, solid wood’s natural grain adds aesthetic value, though laser cutting may darken edges (mitigated by reducing power density).

4. Textile Materials: Natural and Synthetic Fibers

Laser cutting has revolutionized the textile industry by enabling precision cutting of fabrics without fraying, eliminating the need for sewing or heat sealing. CO₂ lasers (20–80 W) are preferred, as they seal edges via thermal fusion for synthetic fibers and produce clean cuts for natural fibers.

- Cotton: A natural cellulose fiber with excellent laser cuttability. CO₂ lasers (30–60 W) cut cotton at 1–5 m/min for 0.5–3 mm thicknesses (fabric stacks), producing fray-free edges. Used in fashion apparel, home textiles, and medical gauze, cotton’s low melting point (decomposes at 350°C) requires moderate power to avoid charring.

- Leather (Natural and Artificial): Natural leather (cowhide, sheepskin) and synthetic leather (PU, PVC-free alternatives) are processed with CO₂ lasers (40–80 W). Cutting speeds range from 0.2–1 m/min for 1–3 mm thicknesses, enabling intricate patterns (e.g., lace designs, perforations) for fashion accessories (bags, shoes) and upholstery. Natural leather’s porous structure requires lower power to prevent burning, while synthetic leather benefits from thermal edge sealing.

- Polyester and Polyester Blends: Synthetic fibers with high thermal stability, polyester (PET) and its blends (e.g., polyester-cotton) cut cleanly with CO₂ lasers (20–50 W) at 1–6 m/min for fabric stacks up to 5 mm. The laser’s heat seals edges, eliminating fraying—a critical advantage for activewear, curtains, and industrial textiles.

- Felt: A non-woven fabric (wool or synthetic) with excellent laser responsiveness. CO₂ lasers (30–60 W) cut felt at 0.5–3 m/min for 1–10 mm thicknesses, producing precise, dimensionally stable shapes for crafts, industrial gaskets, and sound insulation.

5. Paper and Cardboard

Paper and cardboard are low-cost, high-speed laser cutting materials, compatible with CO₂ lasers (10–40 W). The process produces clean, burr-free edges and enables intricate die-cutting without the need for expensive metal dies, making it ideal for short-run production.

- Paper (60–300 g/m²): Laser cutting speeds range from 2–10 m/min for 80–120 g/m² paper, with kerf widths <0.1 mm. Used in greeting cards, invitations, and packaging inserts, paper requires low power (10–20 W) to avoid burning—especially for lightweight grades (≤80 g/m²).

- Cardboard (200–1000 g/m²): Corrugated cardboard (E-flute, B-flute) and solid cardboard are cut with CO₂ lasers (20–40 W) at 0.5–3 m/min for 1–10 mm thicknesses. The laser vaporizes the paper core and liners without crushing flutes, preserving structural integrity. Applications include custom packaging, point-of-purchase displays, and architectural models.

6. Glass and Ceramics: Engraving and Etching

While glass and ceramics cannot be mechanically cut with lasers (due to brittleness and high melting points), they are suitable for laser engraving and etching using pulsed fiber lasers (1–5 kW) or Nd:YAG lasers. The process ablates the surface layer (0.1–10 μm depth) to create frosted or detailed patterns without compromising structural integrity.

- Glass: Borosilicate (laboratory glassware), soda-lime (packaging, decorative glass), and fused silica (optical components) are engraved with pulsed fiber lasers (pulse duration 1–10 ns) at 0.1–1 m/min. Engraving depth is controlled via power (1–3 kW) and pulse frequency (10–100 kHz), producing high-contrast patterns for awards, sensors, and architectural glass.

- Ceramics: Alumina (Al₂O₃) and zirconia (ZrO₂) ceramics are engraved with Nd:YAG lasers (2–5 kW) for industrial applications (e.g., sensor housings, dental implants). The laser ablates the ceramic surface at 0.05–0.5 m/min, creating precise markings or micro-features with minimal thermal shock.

Critical Selection Criteria for Laser Cutting Materials

To optimize laser cutting performance, manufacturers must align material properties with laser parameters and application requirements. Key considerations include:

1. Material Properties

- Optical Absorptivity: Match laser wavelength to material (e.g., fiber lasers for metals, CO₂ for non-metals).

- Thermal Conductivity: High-conductivity materials (copper, aluminum) require higher laser power and faster speeds.

- Moisture Content: Woods and plastics with >12% moisture exhibit poor cut quality (porosity, burning).

- Chemical Composition: Avoid materials emitting toxic fumes (PVC, PUR) or prone to thermal degradation (polystyrene at high power).

2. Technical Parameters

- Thickness: Thicker materials (≥20 mm for metals, ≥25 mm for wood) require high-power lasers (≥10 kW) and slower speeds, increasing production costs.

- Laser Power and Mode: Continuous-wave (CW) lasers for high-volume cutting; pulsed lasers for precision applications (e.g., thin metals, ceramics).

- Assist Gas: Oxygen (enhances cutting for ferrous metals), nitrogen (oxide-free edges for metals/plastics), argon (inert atmosphere for titanium/ceramics).

3. Application Requirements

- Tolerance: Aerospace and medical applications demand ±0.01–±0.05 mm precision, favoring metals and engineered plastics.

- Aesthetics: Transparent materials (acrylic, glass) require nitrogen assist gas to avoid yellowing; wood/leather may need post-finishing (sanding, staining) to reduce charring.

- Mechanical Performance: Structural components (titanium aerospace parts) require minimal HAZ (<0.1 mm) to preserve strength; flexible materials (textiles, PE) need edge stability to prevent fraying.

Key Advantages of Laser Cutting Across Materials

Laser cutting’s technical superiority is underscored by quantifiable benefits that drive industrial adoption:

- Precision: Dimensional accuracy of ±0.01–±0.1 mm and kerf widths <0.5 mm enable complex geometries (e.g., micro-channels in electronics, intricate patterns in textiles).

- Throughput: Cutting speeds up to 10 m/min for thin materials (1 mm steel, polyester fabric) reduce production cycle times by 30–50% vs. traditional methods.

- Material Efficiency: Nest optimization software and narrow kerfs reduce waste by 15–25%, enhancing sustainability and cost-effectiveness.

- Versatility: A single laser system can process metals, plastics, wood, and textiles, eliminating the need for multiple cutting technologies.

- Low Post-Processing: Clean, precise edges reduce finishing time by 60–80%—critical for high-volume production (e.g., automotive components, packaging).

Conclusion

Laser cutting’s compatibility with a diverse range of materials—from high-strength titanium to delicate cotton—stems from its ability to adapt to material-specific properties via laser wavelength, power, and process parameters. By understanding the technical nuances of each material category (e.g., absorptivity, thermal conductivity, structural stability), manufacturers can unlock the full potential of laser cutting to achieve precision, efficiency, and innovation.

Whether producing aerospace-grade metal components, custom acrylic signage, or intricate textile patterns, laser cutting delivers consistent, high-quality results that meet the demands of modern manufacturing. As laser technology advances (e.g., higher-power fiber lasers, AI-driven process optimization, digital twin integration), its material compatibility and performance will continue to expand, solidifying its role as a transformative technology across industries.

For engineers, designers, and procurement professionals, selecting the right material for laser cutting requires a holistic analysis of technical requirements, cost constraints, and application goals. By leveraging the insights outlined above, stakeholders can make informed decisions that maximize productivity, minimize waste, and drive competitive advantage in an increasingly automated manufacturing landscape.