Laser welding is a high-precision fusion joining technology that utilizes a highly collimated, monochromatic laser beam as a concentrated thermal energy source to melt and fuse the interface of target workpieces. Upon rapid solidification, the molten material forms a metallurgically bonded joint with exceptional structural integrity. Distinguished by its localized heat input, minimal thermal distortion, and ultra-fine weld seam control, this technique is compatible with a broad spectrum of materials—including ferrous/non-ferrous metals, engineering plastics, and even advanced ceramics—and has become a foundational process in precision manufacturing, aerospace engineering, and microelectronics industries.

The core mechanism of

laser welding relies on the conversion of photon energy into thermal energy upon the laser beam’s interaction with the workpiece surface. The beam’s energy density, which can exceed 10⁶ W/cm², rapidly elevates the local temperature above the material’s melting point, creating a confined molten pool. The non-contact nature of energy delivery eliminates physical tool wear and workpiece contamination, while the ability to precisely modulate beam parameters (e.g., power density, pulse duration, scanning speed, and focal spot diameter) enables tailored control over weld penetration depth, seam geometry, and solidification rate. This level of process tunability allows laser welding to be seamlessly integrated into automated production lines, supporting consistent, repeatable weld quality for high-volume manufacturing scenarios.

Laser welding processes are categorized into two primary technical configurations, each optimized for distinct application requirements:

1. Conduction Limited Welding (CLW)

This low-energy-density variant restricts heat propagation to the workpiece surface via thermal conduction, resulting in shallow weld penetration (typically <1 mm) and a wide, smooth weld bead. The absence of deep material melting minimizes thermal stress and warpage, making CLW ideal for joining thin-gauge sheets (0.1–1 mm), delicate components, or parts requiring post-weld aesthetic finishes. Key applications include microelectronic packaging, thin-film sensor assembly, and jewelry repair, where preservation of component integrity and surface smoothness is paramount.

2. Keyhole Welding (KW)

High-energy-density laser beams generate sufficient pressure to vaporize the target material, forming a narrow, cylindrical vapor channel (termed the "keyhole") that penetrates the workpiece thickness. Molten material flows around the keyhole and solidifies behind the moving beam, creating a deep, narrow weld seam with a high aspect ratio (depth-to-width ratio >4:1). This configuration is engineered for thick-section materials (1–50 mm) and structural components demanding superior load-bearing capacity. Keyhole welding is the preferred method for heavy industries such as shipbuilding, pipeline fabrication, and aerospace component manufacturing, where joint strength and structural reliability are critical.

Industry-Specific Applications of Laser Welding

The versatility of laser welding stems from its ability to address unique manufacturing challenges across diverse industrial sectors, as outlined below:

Automotive Manufacturing

Laser welding is a cornerstone technology in modern automotive production, driving advancements in lightweighting, structural safety, and electric vehicle (EV) manufacturing. Its key applications include:

- Body-in-White (BIW) Assembly: Joining high-strength steel (HSS) and aluminum alloy panels to reduce vehicle weight while enhancing crashworthiness; laser welding enables lap and butt welds with minimal flange widths, optimizing material utilization.

- EV Battery Pack Fabrication: Sealing battery cell housings, welding busbars, and joining electrode tabs with sub-millimeter precision to ensure electrical conductivity and thermal stability, critical for battery performance and safety.

- Powertrain Component Manufacturing: Welding engine cylinder heads, transmission gears, and turbocharger components, where the process’s minimal heat input preserves the mechanical properties of heat-sensitive alloys.

Integrated with robotic systems and real-time quality monitoring tools, laser welding lines achieve cycle times of <10 seconds per weld, supporting the high-volume production demands of the automotive industry.

Electronics and Microelectronics

The electronics sector relies on laser welding for the assembly of miniaturized, high-precision components, where conventional welding methods risk thermal damage. Key applications include:

- Semiconductor Packaging: Welding lead frames to integrated circuits (ICs) and sealing hermetic packages for high-reliability devices used in aerospace and defense applications.

- Printed Circuit Board (PCB) Assembly: Micro-welding of fine wires (diameter <0.05 mm) to PCB pads, enabling the production of compact wearable devices, IoT sensors, and 5G communication modules.

- Consumer Electronics Manufacturing: Sealing smartphone housings, welding camera modules, and joining flexible display components, where the process’s non-contact nature eliminates component deformation.

The minimal Heat-Affected Zone (HAZ) of laser welding—often <50 μm—prevents damage to adjacent sensitive components, ensuring the long-term reliability of electronic devices.

Medical Device Manufacturing

Laser welding is indispensable in the production of medical devices, where sterility, biocompatibility, and precision are governed by stringent regulatory standards (e.g., ISO 13485, FDA 21 CFR Part 820). Key applications include:

- Implantable Device Fabrication: Welding orthopedic implants (e.g., hip stems, spinal rods), cardiovascular stents, and pacemaker enclosures using biocompatible alloys such as titanium and nitinol; the process’s clean, contamination-free operation eliminates the need for post-weld cleaning.

- Surgical Instrument Production: Joining precision cutting tools, endoscopic components, and laser scalpel tips, where the smooth weld seams reduce tissue irritation during clinical use.

- Diagnostic Equipment Assembly: Welding components for MRI machines, blood analyzers, and ultrasound probes, where the process’s accuracy ensures the functionality of high-precision sensing elements.

Aerospace and Defense

The aerospace industry demands welding solutions that can join advanced materials (e.g., titanium alloys, nickel-based superalloys, carbon fiber-reinforced polymers (CFRPs)) while meeting strict weight and performance requirements. Key applications include:

- Aircraft Structure Fabrication: Welding fuselage panels, wing spars, and landing gear components; laser welding’s high strength-to-weight ratio joints contribute to fuel efficiency and aircraft range.

- Aerospace Engine Manufacturing: Joining turbine blades, combustion chambers, and exhaust nozzles, where the process’s ability to weld dissimilar materials supports the development of next-generation high-thrust engines.

- Satellite and Spacecraft Assembly: Welding lightweight structural frames and propulsion system components, where the vacuum-compatible nature of laser welding eliminates gas porosity in welds.

Jewelry and Luxury Goods Manufacturing

Laser welding’s precision and minimal thermal impact make it a preferred technique for jewelry repair and customization, as well as the production of high-end luxury goods:

- Jewelry Repair: Mending broken chains, resizing rings, and attaching gemstone settings without damaging surrounding precious metals or stones; the focused laser beam allows for localized repairs on intricate designs.

- Custom Jewelry Fabrication: Welding dissimilar metals (e.g., gold and platinum) to create unique aesthetic effects, and engraving fine patterns on metal surfaces with micron-level precision.

- Luxury Watch Manufacturing: Welding watch cases, gears, and decorative components, where the process’s accuracy ensures the functional and aesthetic integrity of high-value timepieces.

Laser Welding Equipment and System Configuration

Industrial laser welding systems are engineered for precision, automation, and safety, with core components tailored to specific application requirements:

1. Laser Source

The primary classification of laser sources includes fiber lasers (high efficiency, low maintenance, ideal for metal welding), CO₂ lasers (suited for non-metallic materials such as plastics), and Nd:YAG/Nd:YVO₄ lasers (pulsed operation for micro-welding applications). Power outputs range from <100 W for microelectronics to >10 kW for heavy industrial keyhole welding.

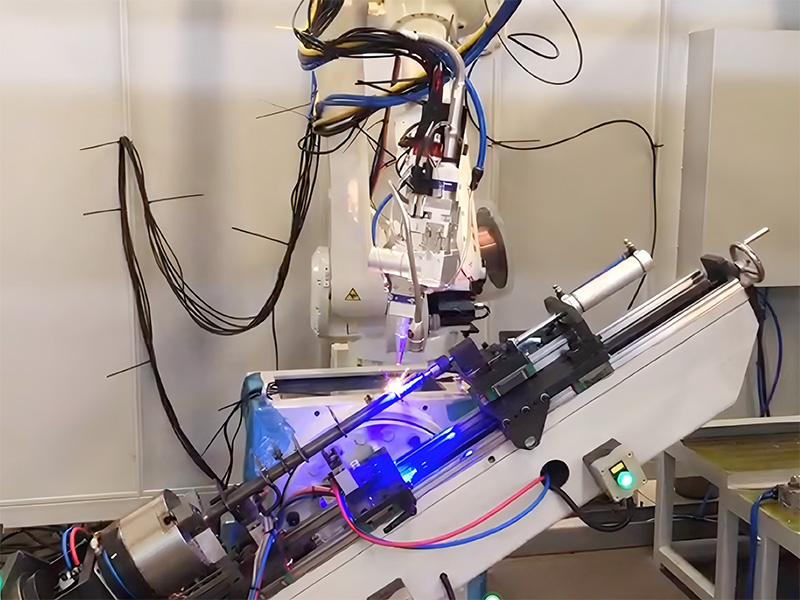

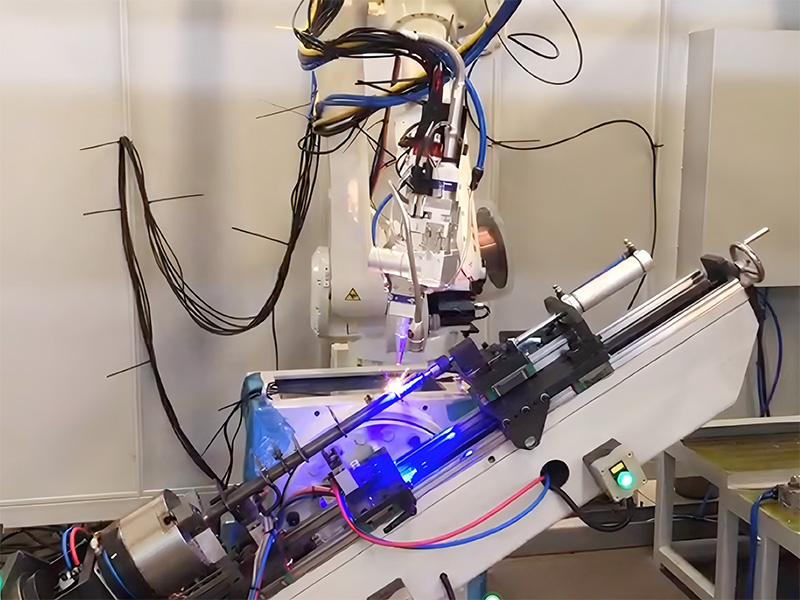

2. Welding Workstation

A typical workstation integrates the laser source, a CNC-controlled positioning system (e.g., robotic arm, gantry system), beam delivery optics (e.g., fiber optic cables, galvanometers), and safety features (e.g., laser safety enclosures, interlocks, fume extraction systems). For high-precision applications, vision-guided positioning systems and real-time weld monitoring tools (e.g., thermal imaging cameras, plasma sensors) are integrated to detect and correct process deviations.

3. Automated Integration

Modern laser welding systems are often integrated with manufacturing execution systems (MES) and computer-aided design (CAD) software, enabling offline programming, process simulation, and traceability of weld parameters. This integration supports Industry 4.0 initiatives, optimizing production efficiency and quality control.

Core Advantages of Laser Welding Over Conventional Welding Methods

Laser welding outperforms traditional techniques (e.g., arc welding, resistance welding) in several critical aspects:

- Unmatched Precision and Minimal Distortion: The focused laser beam creates narrow weld seams and a minimal HAZ, preserving the mechanical properties of the base material and eliminating the need for post-weld machining.

- High Processing Speed and Efficiency: Laser welding achieves travel speeds of up to 50 m/min for thin materials, significantly reducing production cycle times compared to arc welding.

- Material Versatility: The process can join dissimilar materials (e.g., metal-plastic, aluminum-steel) that are incompatible with conventional welding methods.

- Environmentally Friendly Operation: Laser welding produces minimal waste, eliminates the need for consumables (e.g., welding rods, fluxes), and generates low levels of noise and emissions, aligning with global sustainability goals.

- Automation Compatibility: The non-contact nature of laser welding enables seamless integration with robotic systems, supporting 24/7 high-volume production with consistent quality.

Key Challenges and Mitigation Strategies

Despite its advantages, laser welding presents several implementation challenges that require targeted solutions:

- High Initial Capital Investment: Laser welding systems have higher upfront costs compared to conventional welding equipment. Mitigation strategies include leasing options, modular system configurations, and ROI analysis based on long-term savings from reduced rework and material waste.

- Technical Expertise Requirements: Operating and maintaining laser welding systems requires specialized training in beam parameter optimization, material science, and safety protocols. Companies can address this by partnering with technical training institutions or hiring certified laser welding technicians.

- Material-Specific Limitations: High-reflectivity materials (e.g., copper, aluminum) can reflect up to 90% of incident laser energy, reducing process efficiency. Mitigation techniques include using high-brightness fiber lasers, pre-heating the workpiece, and applying anti-reflective coatings.

- Beam Transmission Loss: Long-distance beam delivery via fiber optics can result in energy attenuation. This challenge is addressed by using low-loss optical fibers and regular maintenance of beam delivery components.

Conclusion

Laser welding is a transformative joining technology that has redefined precision manufacturing across automotive, electronics, medical, aerospace, and luxury goods industries. Its unique combination of high precision, material versatility, and automation compatibility makes it an indispensable tool for addressing the evolving demands of modern manufacturing. As laser source technology advances (e.g., higher power, lower cost) and artificial intelligence is integrated into process monitoring systems, laser welding will continue to expand its application scope, enabling the development of innovative products and sustainable manufacturing practices. For organizations seeking to enhance product quality, reduce production costs, and gain a competitive edge, understanding and adopting laser welding technology is a strategic imperative.

Would you like me to further refine the technical parameter details or industry case studies in this article to make it more targeted to a specific sector?