APPLICATION

APPLICATION

ABOUT US

Jiangsu Dade Heavy Industry Co., Ltd. (stock code: 870547) is a high-tech enterprise with independent knowledge industry that integrates research and development, manufacturing, sales and services. The company has a registered capital of 13 million yuan, total assets of approximately 150 million yuan, and nearly 600 employees. It is located in Sunshine Industrial Park, Xishan District, Wuxi City, Jiangsu Province, covering an area of 100000 square meters.

CASE

CERTIFICATE

NEWS

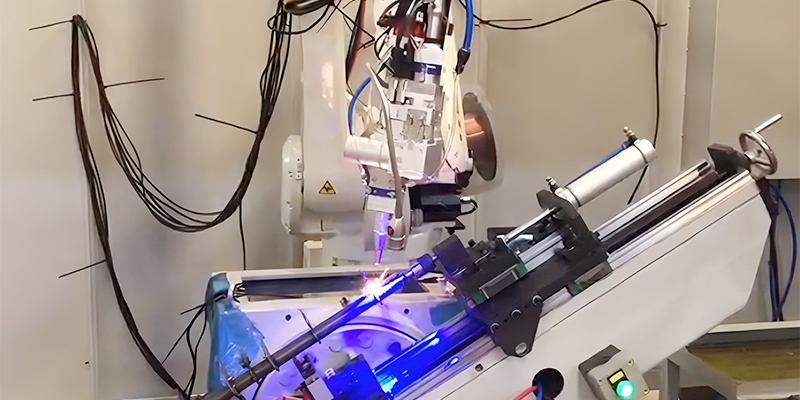

In the era of Industry 4.0, modern manufacturing is defined by the pursuit of operational excellence—where high throughput, consistent quality, and cost optimization converge to drive competitive advantage. Among the critical processes shaping industrial productivity, production line welding stands as a cornerstone, particularly in sectors requiring robust material joining such as automotive, aerospace, heavy equipment, and construction. As a value-adding operation that directly impacts product structural integrity and performance, welding lines are increasingly targeted for optimization through advanced automation, intelligent process control, and precision engineering. By integrating state-of-the-art welding technologies and data-driven workflows, manufacturers can transcend the...

In the era of Industry 4.0, global manufacturing and supply chain ecosystems are undergoing a transformative shift toward automation, digitalization, and intelligent optimization. As the backbone of logistics automation, material handling robots—formally classified as Automated Material Handling Systems (AMHS)—have emerged as critical enablers of operational efficiency, process reliability, and supply chain resilience. These advanced robotic systems redefine the movement, storage, control, and protection of raw materials, work-in-progress (WIP), and finished goods across industrial facilities, warehouses, and distribution centers. By automating labor-intensive, repetitive, and high-risk material handling tasks, they not only address the limitations of manual operations but a...

In the era of Industry 4.0, the manufacturing sector has witnessed a paradigm shift toward automation, precision engineering, and intelligent production—driven by the escalating demand for high-quality components, reduced cycle times, and cost optimization. Robotic cutting systems, as a core subset of advanced manufacturing technology, have redefined material processing across industries ranging from automotive and aerospace to metal fabrication and medical device production. These systems integrate robotic kinematics, advanced cutting mechanisms, and computer numerical control (CNC) to deliver unparalleled efficiency, accuracy, and versatility, addressing the limitations of traditional manual or semi-automated cutting processes. This article provides a technical overview...

MACHINE PURCHASE GUIDE AND SERVICES

Pre-Purchase Analysis

Pre-Purchase Analysis

Before purchasing, please provide the Application drawings or samples you intend to process. Our professional engineering team will conduct a technical analysis and evaluation.

Solution Proposal

Solution Proposal

Based on your Application processing requirements, our engineers will recommend the most suitable equipment and corresponding fixture solutions.

Equipment Purchase

Equipment Purchase

Once satisfied, you may sign a purchase contract and join our esteemed customer network.

Equipment Delivery

Equipment Delivery

Within the agreed delivery period, we will transport the highest-quality Applications to your factory for on-site handover.

Installation Debugging

Installation Debugging

Upon arrival, our professional engineers will install, debug, and provide essential operational guidelines.

Technical Guidance

Technical Guidance

Our engineers will offer technical training to your operators to ensure the processed Applications meet desired specifications.

We provide one-on-one consultative services, offering industry and equipment-related information.

1. Our sales team will thoroughly understand your processing needs and tailor equipment solutions accordingly.

2. We provide industry insights to help you stay informed about market trends.

After signing the contract (or upon purchase intent), we offer comprehensive support.

1. Customized processing solutions and machine selection based on your Application characteristics and Applicationion capacity.

2. Services including cycle time analysis, equipment selection, fixture design, factory layout planning, and free sample processing.

3. Zero-basics technical training. Our engineers will train your operators to meet processing requirements.

Service Commitment: Continuously providing Application consultations, technical guidance, and training is the cornerstone of our development.

MESSAGE